Introduction

Dye sublimation printing is a popular type of screen printing method known for producing high-quality, durable prints. This method has found applications in various industries due to its versatility and the vibrant, long-lasting results it offers. In this article, we will delve into what is dye sublimation printing, its history, applications, advantages, materials, and how it compares to other printing methods.

Understanding Dye Sublimation Printing

Dye sublimation printing is a digital printing technology that uses heat to transfer dye onto materials like fabric, plastic, and metal. The term “sublimation” refers to the transition of the dye from a solid to a gas state without passing through a liquid phase. This unique process results in high-resolution images that are embedded into the substrate, making them resistant to fading and wear. This printing method is favored for its ability to produce vibrant colors and intricate details.

History and Evolution

The concept of sublimation dye can be traced back to the early 20th century. Initially used for industrial applications, it wasn’t until the advent of digital printing technology that dye sublimation became accessible for commercial and consumer use. Over the years, advancements in printer technology and ink formulations have significantly improved the quality and efficiency of the dye sublimation process. Early techniques were limited in scope, but technological advancements have made the process more efficient and accessible.

Applications of Dye Sublimation Printing

Dye sublimation is widely used across various industries due to its ability to produce vibrant and durable prints. Some common applications include:

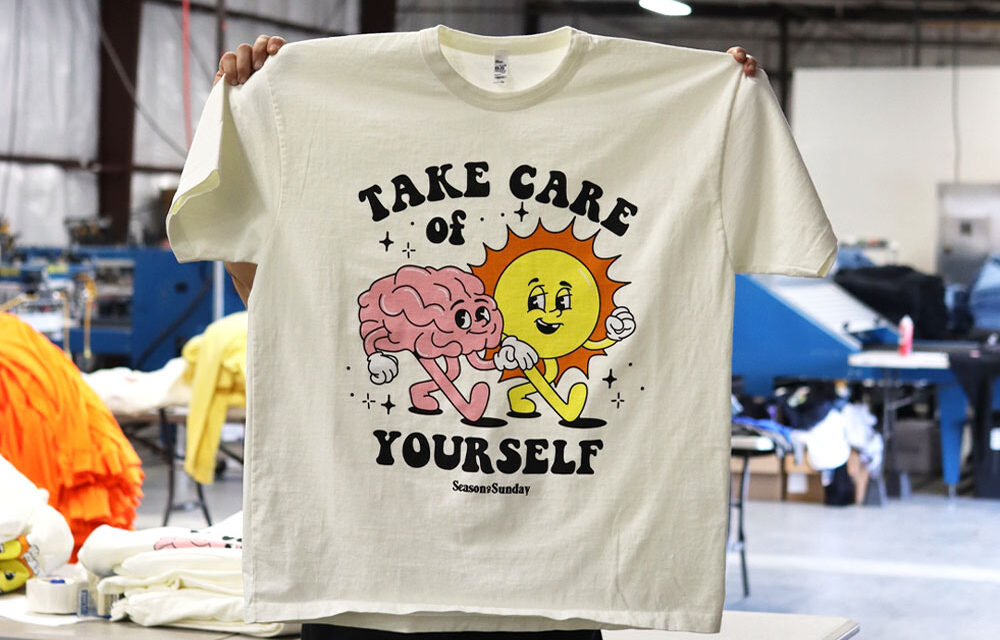

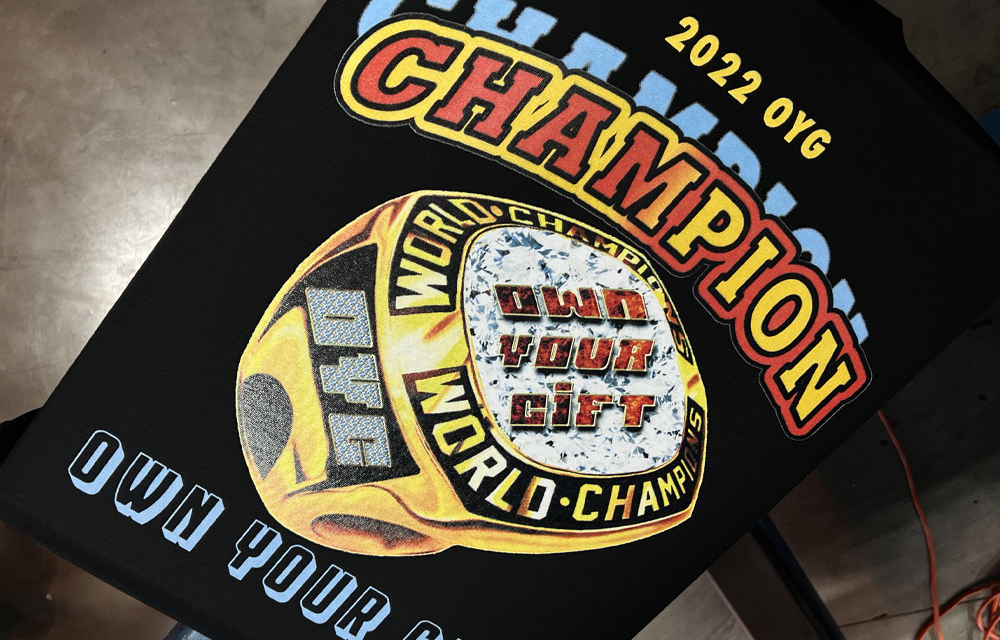

- Textile industry: Used for creating custom apparel, sportswear, and home textiles. The ability to print directly onto fabric with high precision makes dye sublimation ideal for detailed designs and photographic images.

- Signage and banners: Ideal for producing outdoor and indoor signs that are weather-resistant and durable.

- Custom merchandise: Popular for creating personalized items such as mugs, phone cases, and keychains.

- Home décor: Used to produce high-quality prints for decorative items like cushions, curtains, and wall art.

Advantages of Dye Sublimation Printing

Here are the key advantages:

- Superior Quality: The images are sharp, vibrant, and resistant to fading, scratching, and cracking.

- Versatility: This method allows for printing on a wide range of materials, making it highly versatile.

- Environmental Friendliness: The dye sublimation process produces less waste compared to traditional printing methods.

- Durability: Prints created using dye sublimation are durable and retain color over extended periods.

Materials and Substrates

Dye sublimation printing works best on materials that are coated or treated to accept sublimation dyes. Common substrates include polyester fabrics, polymer-coated items like ceramics, metals, and plastics. The ability to print on such a variety of surfaces makes this technique ideal for creating custom products. Polyester fabrics absorb the dye well, resulting in vibrant and long-lasting prints. Polymer-coated items provide a smooth surface that allows the dye to transfer evenly and retain its quality.

Comparing Dye Sublimation with Other Printing Methods

When comparing dye sublimation with other printing techniques, several key differences stand out:

- Screen printing: While screen printing is cost-effective for large runs, it cannot match the detail and color range of dye sublimation. Screen printing is often limited to simpler designs and fewer colors.

- Direct-to-garment printing: This method is suitable for small batches and intricate designs but may not offer the same durability as dye sublimation. Direct-to-garment printing can produce detailed prints, but the colors may not be as vibrant or long-lasting.

- Heat transfer printing: Though similar to sublimation, heat transfer printing typically involves a film layer that can peel or crack over time. Dye sublimation embeds the dye into the material, ensuring that the prints remain intact and resistant to wear.

Conclusion

In conclusion, dye sublimation printing is a versatile and efficient printing method that offers numerous benefits over traditional techniques. Its ability to produce high-quality, durable prints on a variety of substrates makes it an excellent choice for both commercial and personal projects. Understanding what is dye sublimation and how does sublimation work can help you appreciate the advantages this technology brings to the world of printing. By offering vibrant, long-lasting prints that maintain their quality over time, dye sublimation stands out as a premier printing method.