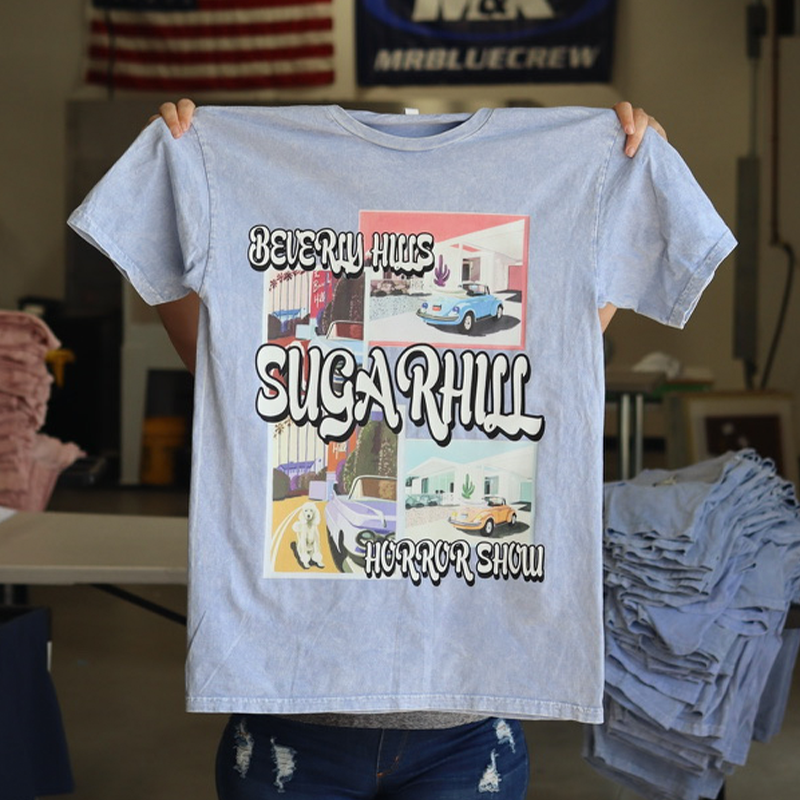

Wholesale Digital Screen Printing

What is Digital Screen Printing?

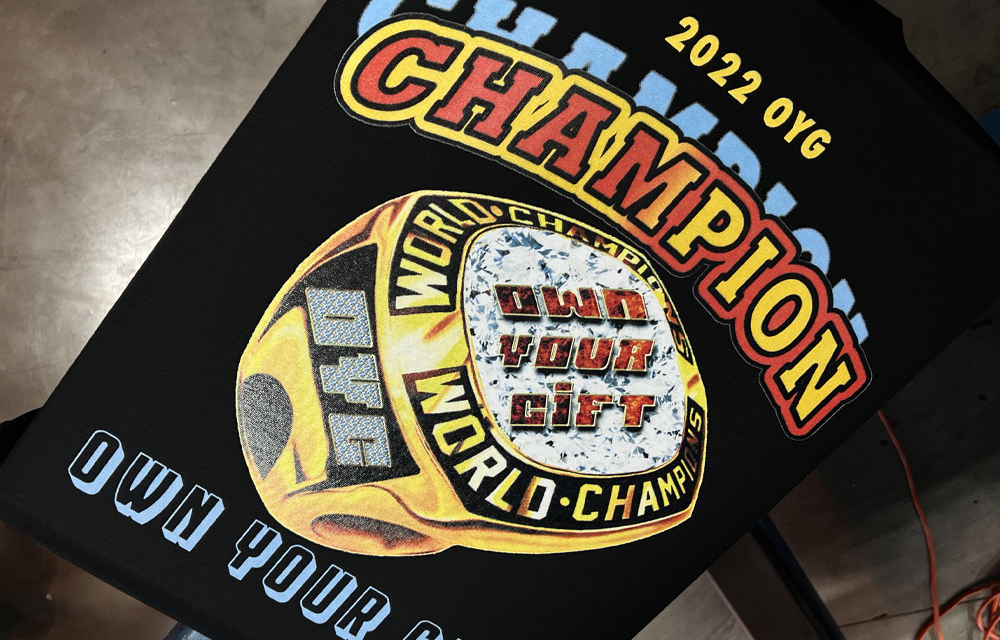

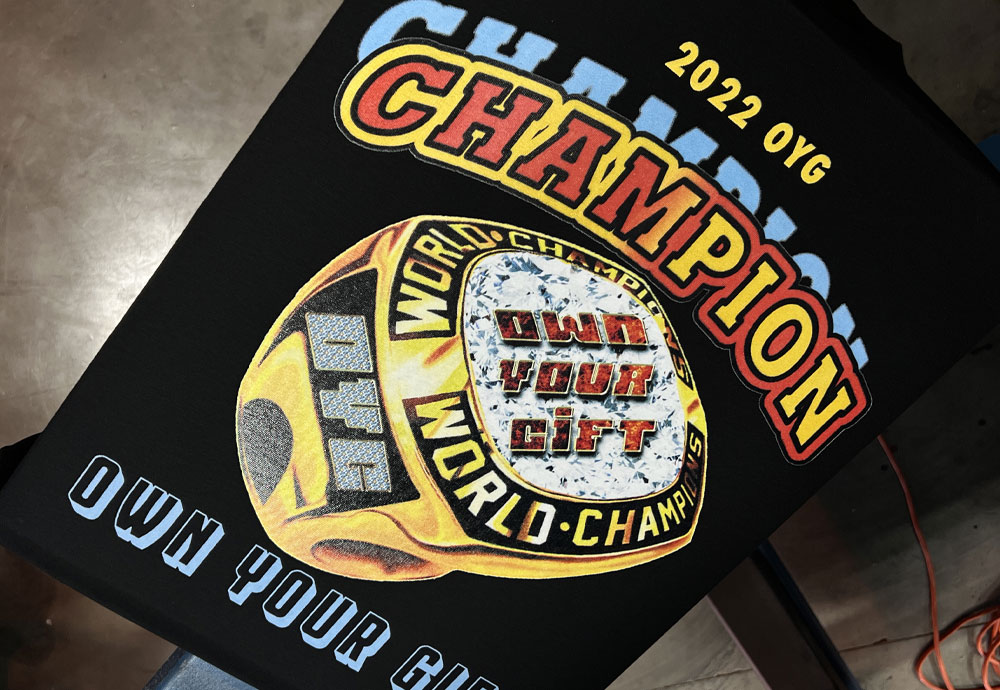

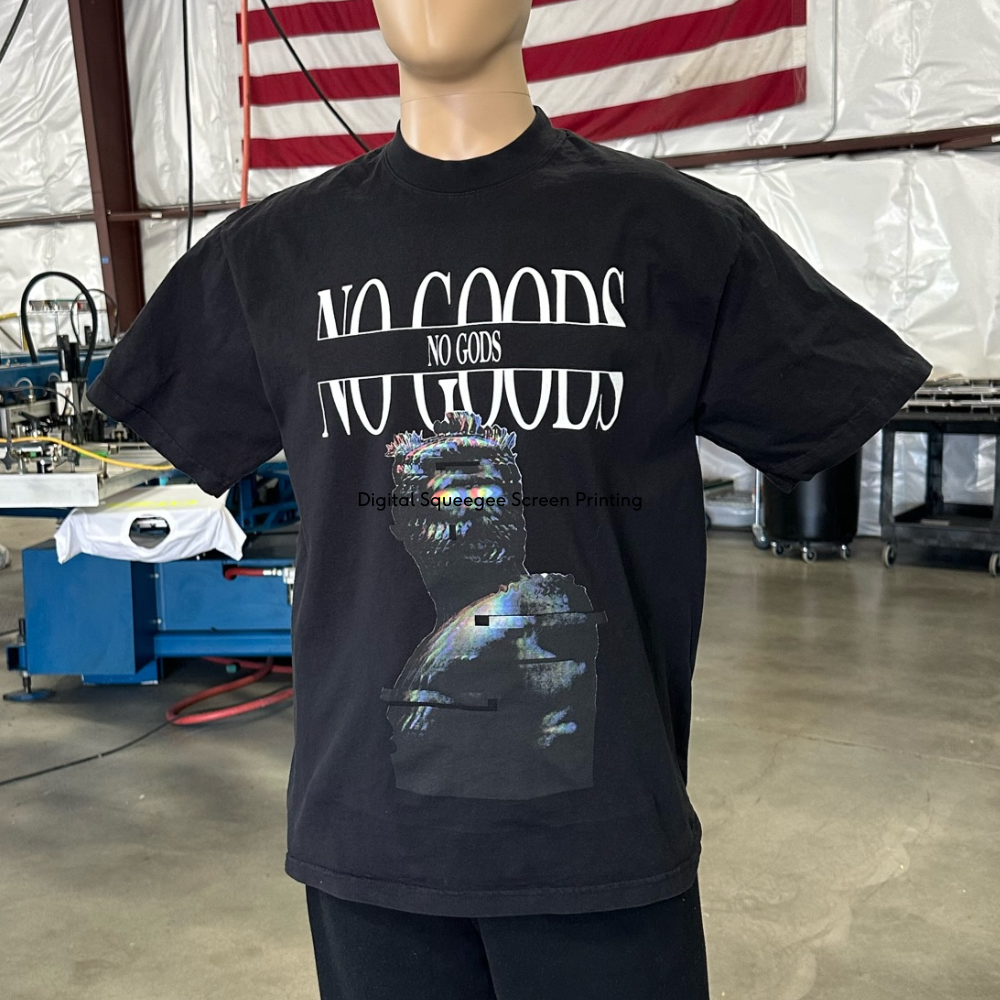

Digital screen printing is a hybrid printing technology that combines traditional screen printing and digital printing into one process. Specifically, it integrates the high production speed of screen printing for the under base with the detailed graphic capabilities of digital printing for the overlay.

- Reduced Pricing For Photo Realistic & Full Color Printing

- Utilizes water base ink that's eco friendly

- Can be printed on nearly any type of fabric

- Soft to the touch and feels like a water base screen print