Digital printing has revolutionized the world of printing, offering unprecedented speed, accuracy, and versatility. This modern technique stands out for its ability to produce high-quality prints quickly and efficiently. Understanding the process of digital printing is essential for anyone looking to leverage its advantages for business, creative projects, or personal use.

Introduction to Digital Printing

This screen printing method involves printing digital-based images directly onto various media substrates. Unlike traditional printing methods, such as offset printing, digital printing does not require printing plates. This significant difference reduces setup time and costs, making it ideal for short-run printing projects. The digital printing process can handle various media types, including paper, canvas, fabric, and synthetics, providing flexibility for numerous applications.

How Digital Printing Works

The digital printing process begins with the creation of a digital file, typically in formats like PDF, JPEG, or TIFF. These files are created using graphic design software or are derived from scanned images. Once the digital file is prepared, it is sent directly to the digital printer.

1. File Preparation and RIP

The first critical step in digital printing is file preparation. This involves ensuring the digital file is in the correct format and resolution for the intended print size. The digital file is then processed by a Raster Image Processor (RIP), which converts the digital file into a bitmap image. The RIP process ensures that the image is compatible with the printer and ready for output.

2. Printer Setup

After the RIP process, the digital printer needs to be set up. Digital printers can vary significantly in size and capability, ranging from desktop printers to large-format printers used for banners and posters. During setup, the printer is calibrated to ensure accurate color reproduction and alignment. Calibration is crucial for maintaining the quality and consistency of the printed images.

3. Printing Process

Once the printer is set up and calibrated, the actual printing begins. Digital printers use various technologies to apply ink or toner to the substrate. The most common technologies are inkjet and laser printing.

- Inkjet Printing: This technology uses tiny nozzles to spray droplets of ink onto the substrate. The ink is either dye-based or pigment-based. Inkjet printing is renowned for its ability to produce high-resolution images with vivid colors, making it ideal for photographic prints and fine art reproductions.

- Laser Printing: Laser printers use a laser beam to produce an image on a drum. The drum then attracts toner particles, which are transferred onto the substrate and fused using heat. Laser printing is known for its speed and efficiency, making it suitable for high-volume printing tasks such as business documents and marketing materials.

4. Finishing and Quality Control

After printing, the prints often undergo finishing processes to enhance their appearance and durability. Finishing options include lamination, varnishing, embossing, and cutting. These processes add a professional touch and protect the prints from wear and tear. Quality control checks are essential at this stage to ensure that the final product meets the required standards.

Advantages of Digital Printing

Digital printing offers several advantages over traditional printing methods:

- Quick Turnaround Time: Digital printing eliminates the need for printing plates, reducing setup time significantly. This allows for faster production and delivery of printed materials.

- Cost-Effective for Short Runs: For small print runs, digital printing is more economical than offset printing, which involves higher setup costs.

- Customization: Digital printing allows for easy customization and personalization of prints. Variable data printing (VDP) enables the production of unique prints with individualized text, images, or graphics.

- High Quality: Digital printing produces high-resolution images with sharp details and vibrant colors. Advanced color management systems ensure consistent and accurate color reproduction.

- Versatility: Digital printers can print on a wide range of substrates, from paper and fabric to metal and glass, making it suitable for various applications.

Applications of Digital Printing

Digital printing is used across various industries for different purposes:

- Marketing and Advertising: Flyers, brochures, posters, and banners are commonly printed digitally due to the need for quick turnaround and high-quality visuals.

- Packaging: Short-run packaging solutions, such as custom labels and boxes, benefit from the flexibility and cost-effectiveness of digital printing.

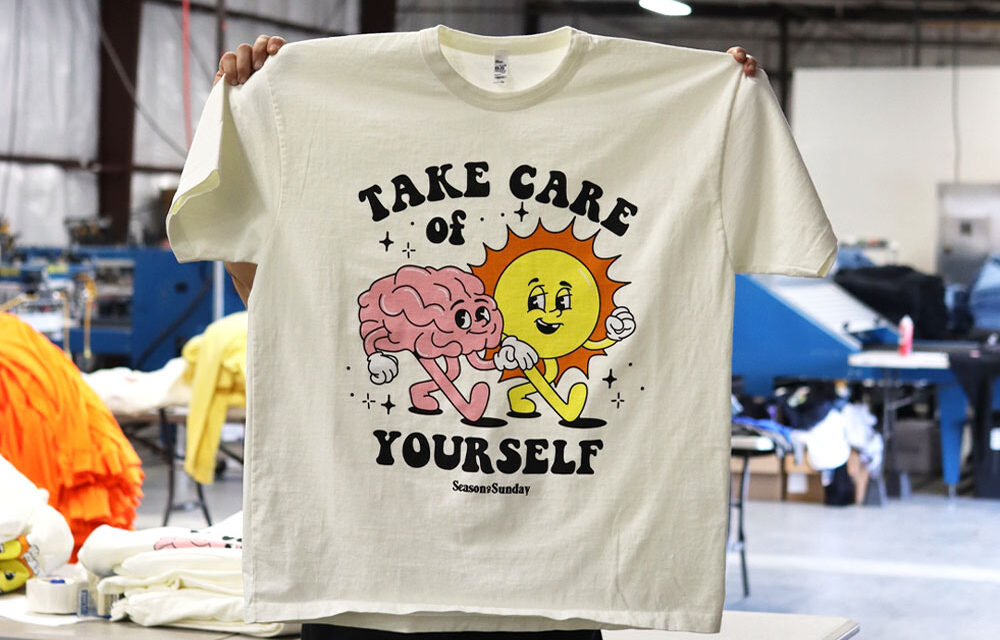

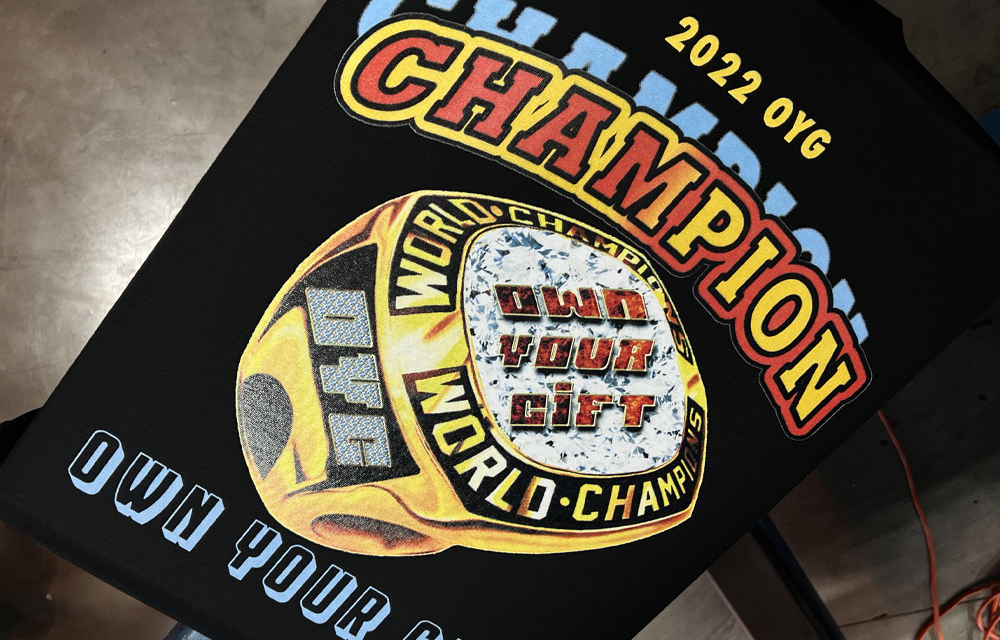

- Textiles: Digital textile printing is popular for producing custom fabrics and clothing items with intricate designs.

- Publishing: Books, magazines, and photo albums are often printed digitally to accommodate small print runs and on-demand printing.

- Fine Art: Artists use digital printing to reproduce their work with exceptional quality, allowing them to sell limited-edition prints.

Conclusion

The process of digital printing has transformed the printing industry by offering a fast, flexible, and cost-effective solution for various printing needs. Its ability to produce high-quality prints on demand makes it a valuable tool for businesses, artists, and individuals alike. As technology continues to advance, digital printing will undoubtedly play an even more significant role in the future of printing. Understanding this process and its benefits can help you make the most of what digital printing has to offer.