Professional Screen Printing Services

Wholesale Custom Screen Printing

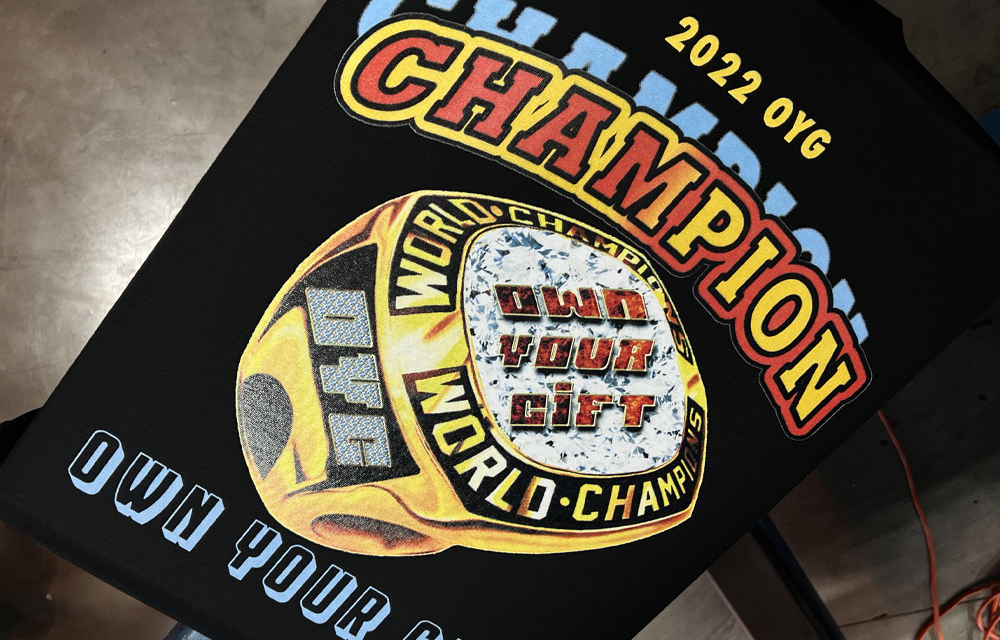

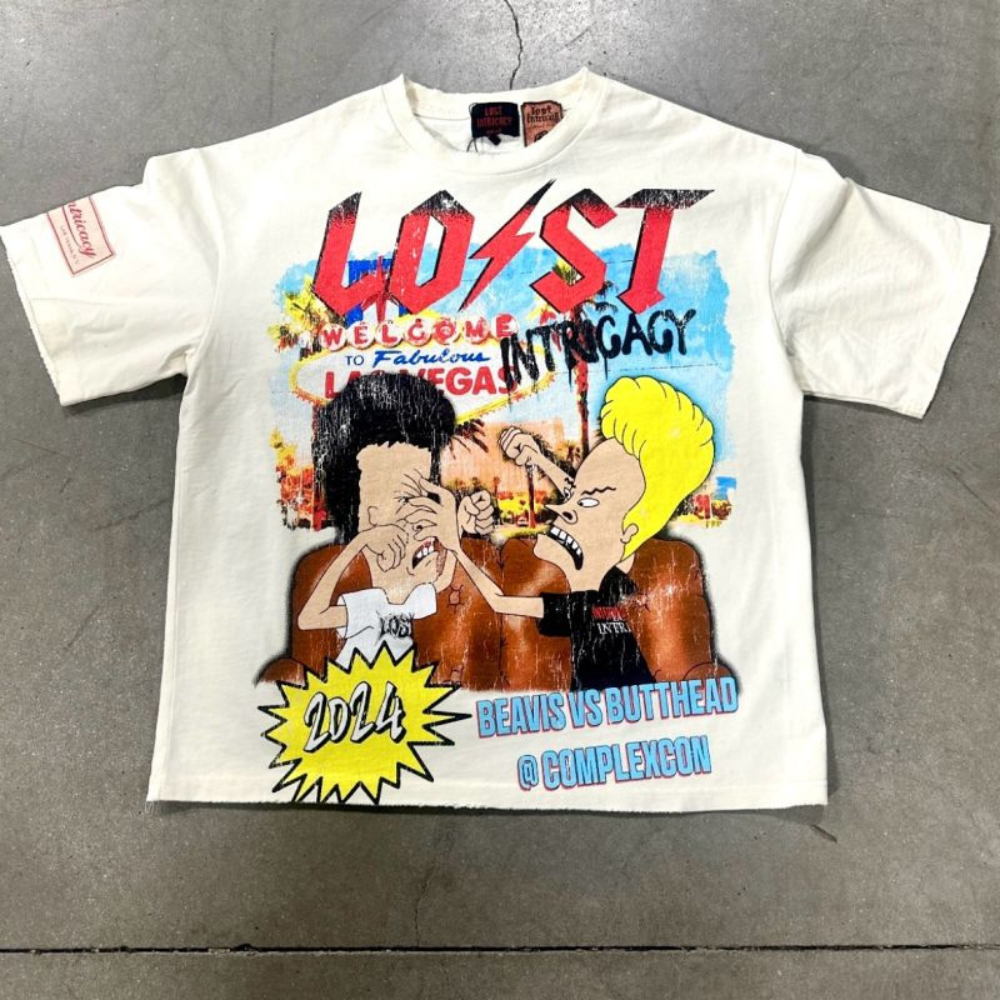

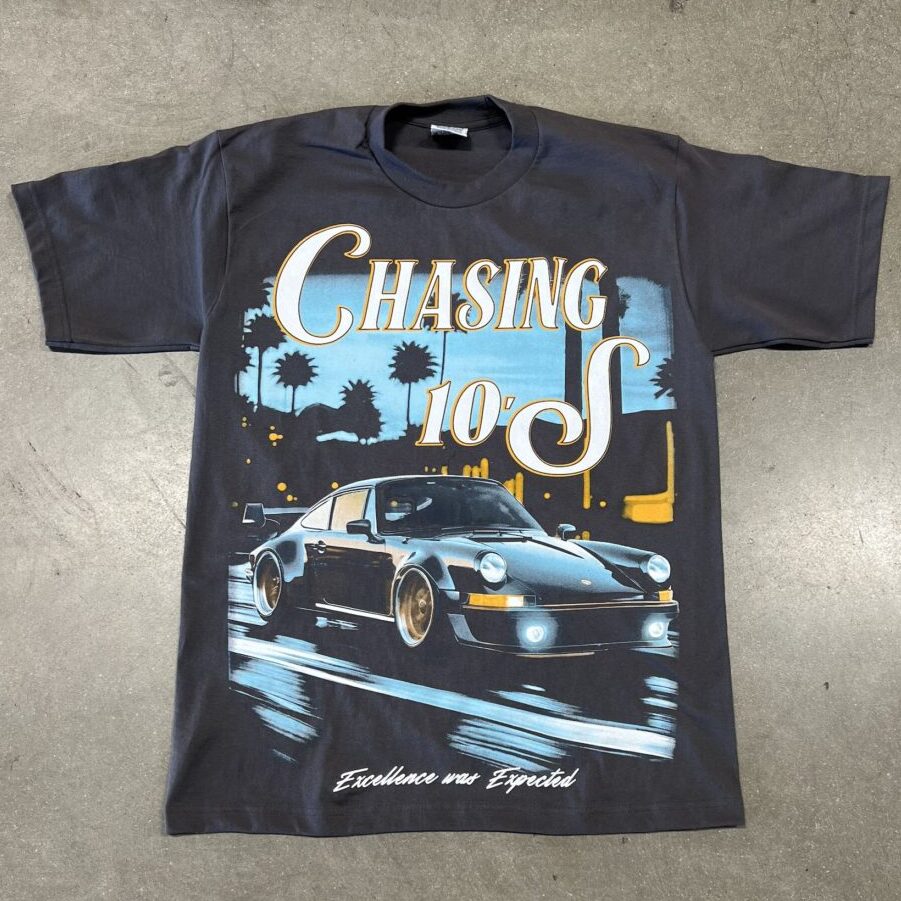

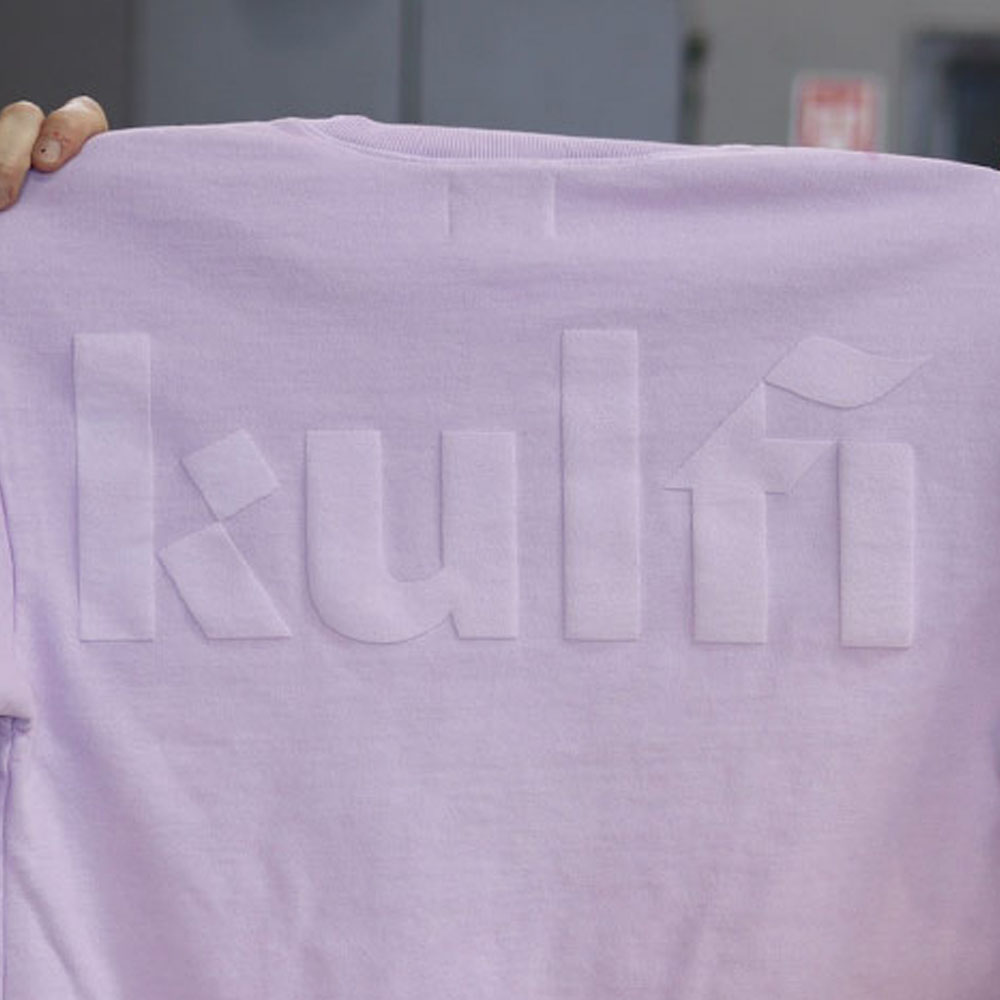

We offer wholesale custom screen printing services for clothing brands and businesses. Our screen printing service is the most popular decoration technique for custom t-shirt printing, custom sweatshirts and hoodies, and much more. Our services included jumbo screen printing, 3d puff printing, digital screen printing, screen printed neck tags, and simulated process screen printing. Plus, our technical capabilities include placements like printing over seams and kangaroo pockets. Best of all, we offer 24-hour rush service and samples before production are standard on every order.

- 50 piece minimum

- Bulk pricing discounts 100+, 250+ and more

- 24 hour rush service

- Wholesale pricing, factory direct

- Custom t-shirts, hoodies, tote bags, & more

- 10 day average turn around

Request a Call Back

An account rep requires a minimum order of 50 pieces to process your order.