A Jumbo Screen Printing Project: A Collaboration Between Online Ceramics and A24 Studios

Project Showcase

| Product | 1801GD Los Angeles Apparel |

|---|---|

| Decoration | Jumbo Screen Print 17.5 x 23 |

| Materials | Made in USA 18 Singles 6.5oz/y2 100% Cotton |

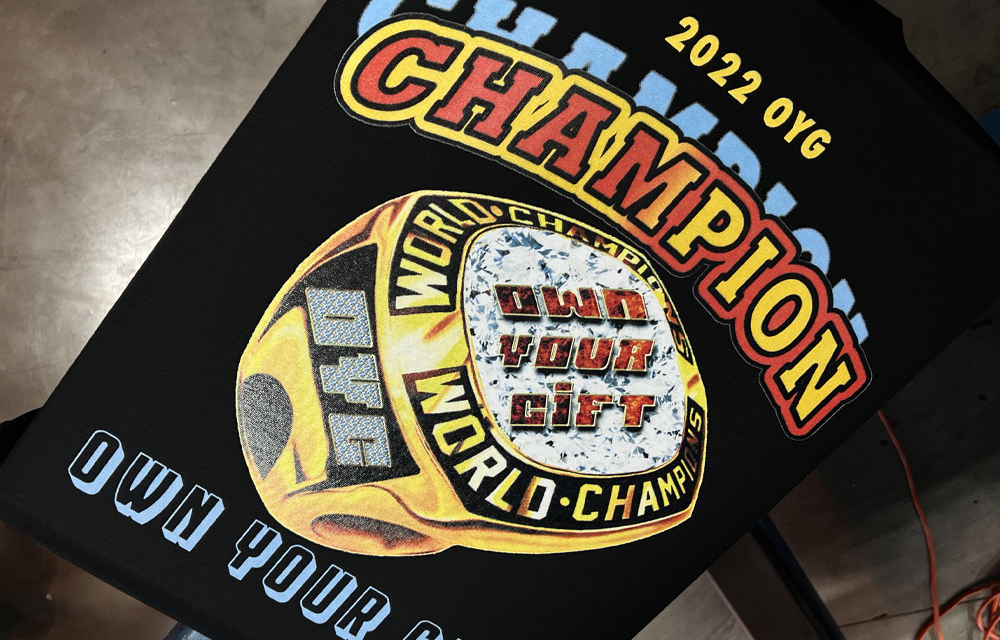

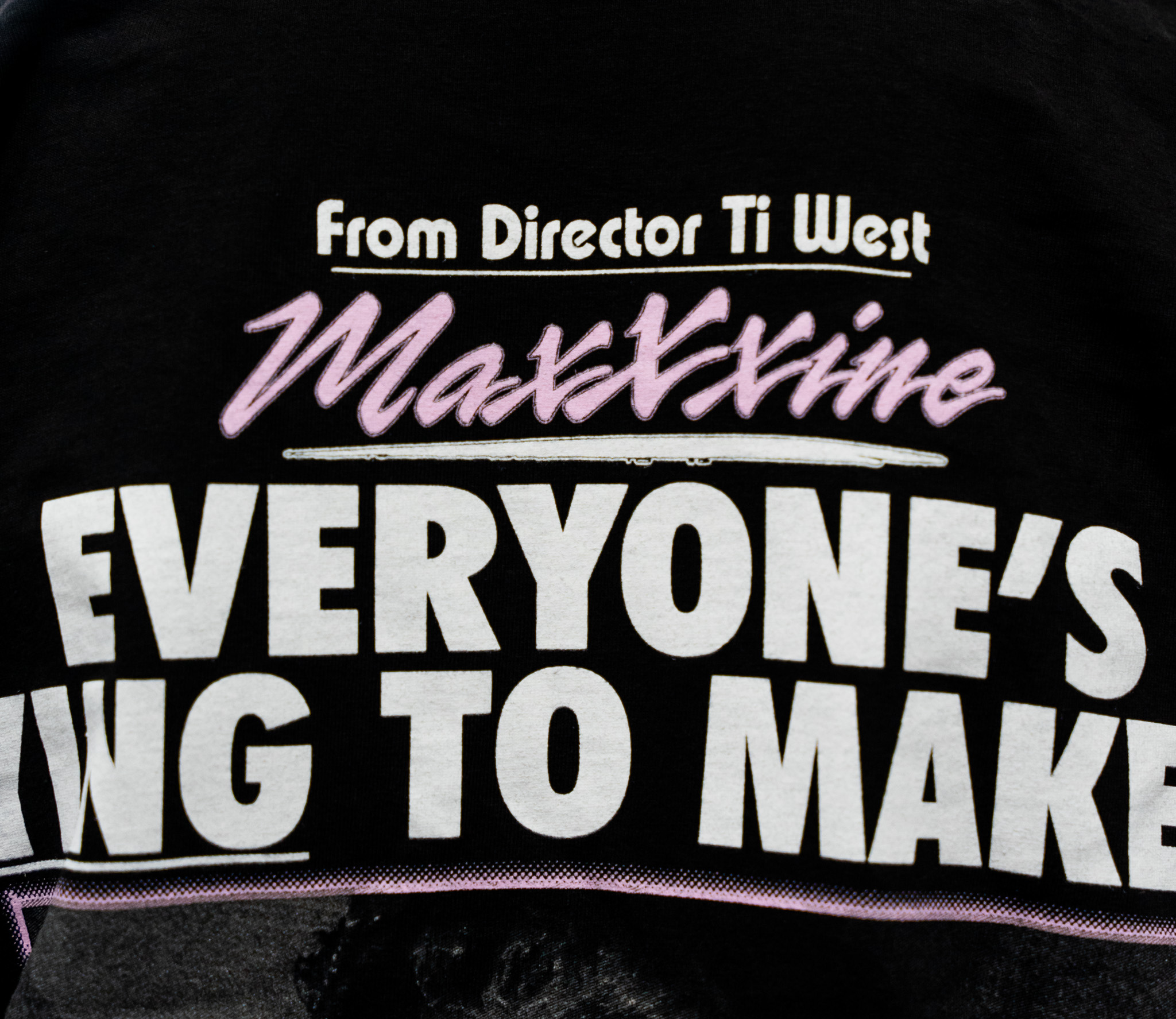

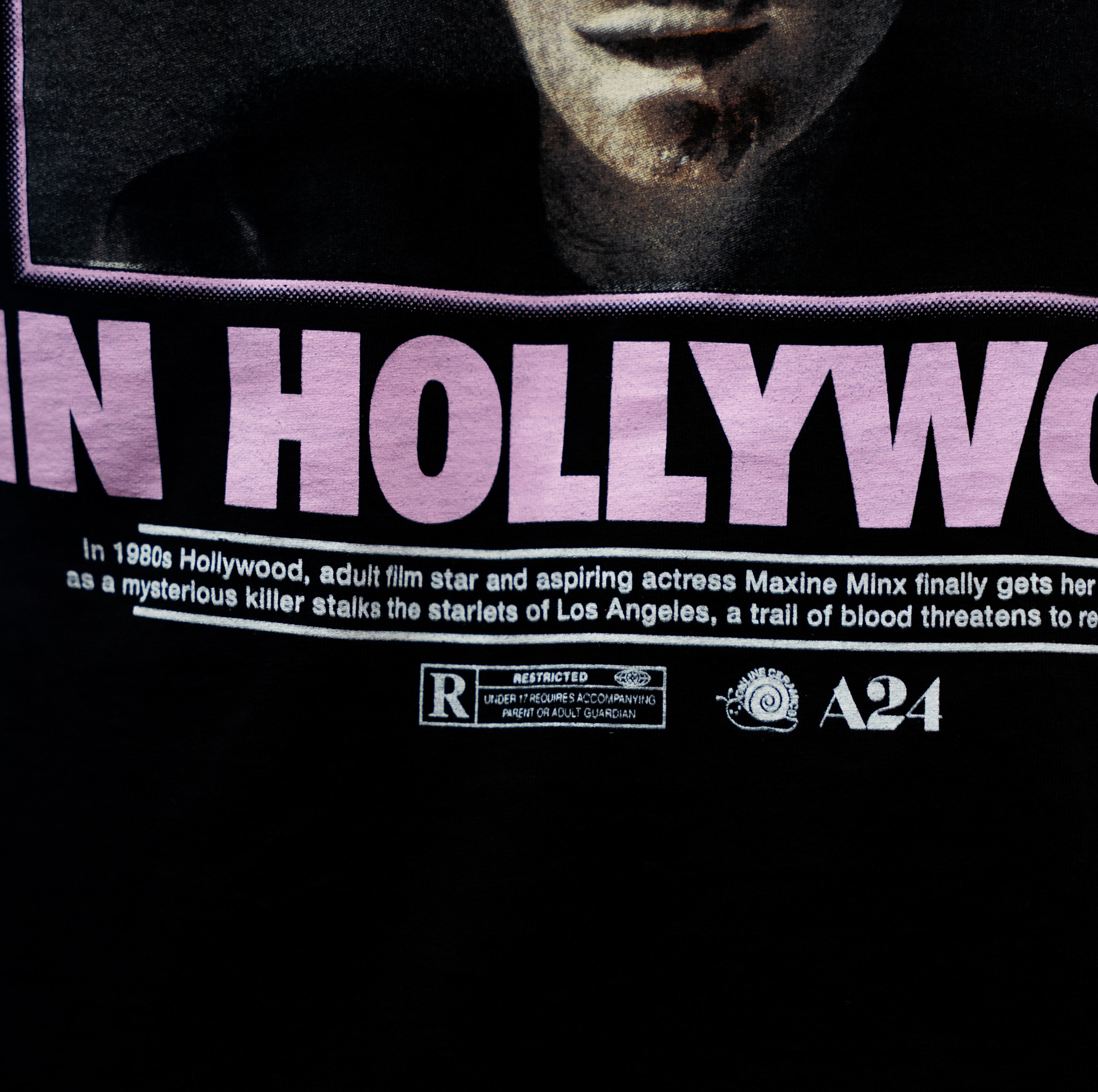

| Design Name | MaxXxine |

| @OnlineCeramics x MaXXXine collection |

A Jumbo Screen Printing Project: A Collaboration Between Online Ceramics and A24 Studios

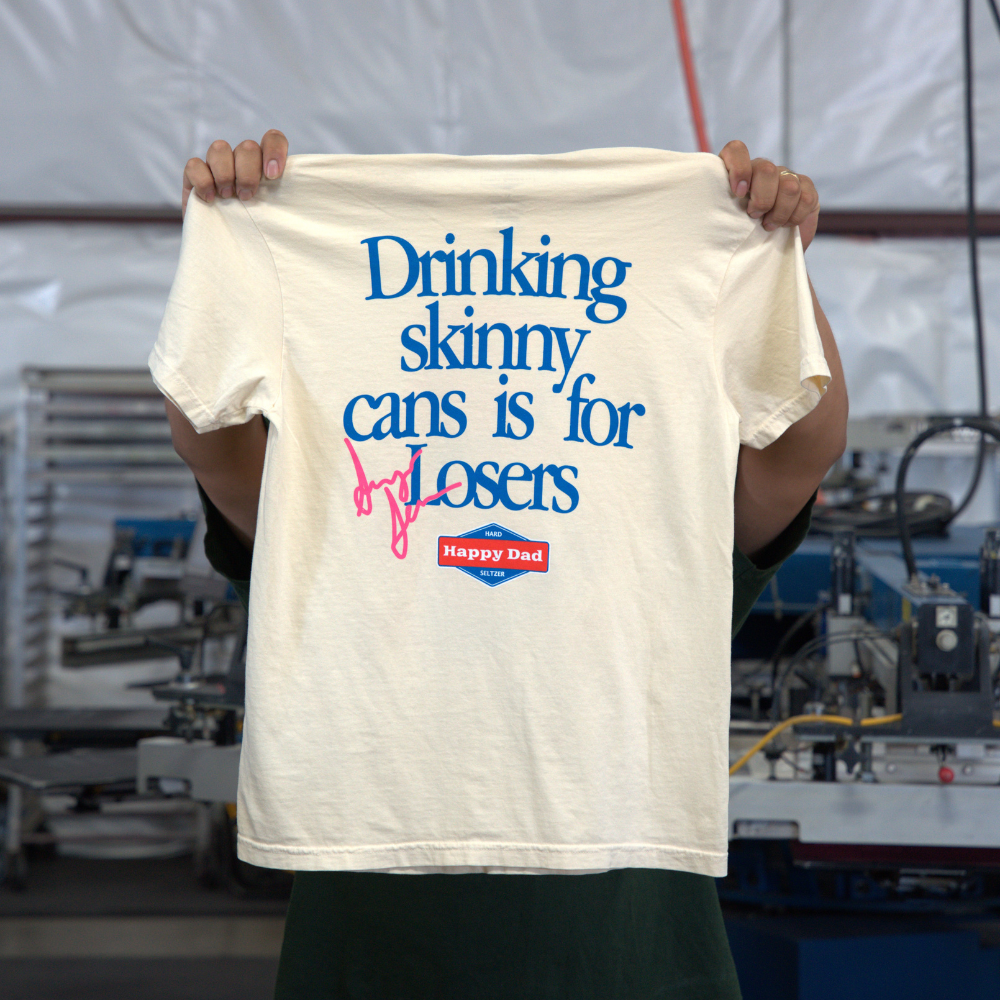

In the bustling world of screen printing, every project presents a unique set of challenges and opportunities. Recently, we created a jumbo screen printing project for a collaboration between Online Ceramics and A24 Studios for their Maxxxine collection. This project involved printing on Los Angeles Apparel 1801GD, a heavyweight 6.5 oz t-shirt, known for its durability and comfort.

The project was no small feat. We screen-printed a whopping 1,500 t-shirts, both front and back, in just 48 hours. The t-shirt design was jumbo, measuring 17″ wide by 23″ tall, covering a significant portion of the t-shirt.

The design was intricate, requiring a 6 color front and 6 color back screen setup. This complexity necessitated the use of halftones, Pantone matching, high detail, and simulated process screen printing.

Halftones, a technique that uses dots of varying sizes and spacing to create a gradient effect, were crucial for achieving the design’s subtle color transitions. Pantone matching was used to ensure color accuracy, vital for maintaining the integrity of the design and meeting the client’s expectations.

Simulated process screen printing, a technique typically used for reproducing photographic or full-color images, was employed to handle the design’s complexity. This method involves the use of color separation software and printing certain colors of opaque inks in a specific order on high mesh count screens.

The screen printing process began with the preparation of the screens. Given the design’s high detail, we used screens with a high mesh count to ensure the design’s intricate details were captured accurately. The screens were coated with emulsion, exposed, and washed out correctly, ensuring no pinholes or other exposed data. Our entire darkroom is fully automated which ensures quick turn arounds, repeatable processes, and accurate re-production on re-orders.

Once the screens were prepared, we moved on to the registration process. Each screen was aligned to the base screen using micro registration. This step is crucial for ensuring that all colors are printed on all garments in a consistent geometric plane, which is vital for maintaining the design’s consistency across all 1,500 t-shirts.

The printing process was done on our M&R Challenger 16/18 screen printing press, ensuring consistent and high-quality prints. The press’s consistency was crucial for ensuring that all colors were consistently printed on all garments.

Ink selection was another critical aspect of this project. We ensured that the ink mixed was an exact PMS match, as PMS or Pantone Matching System is the worldwide standard for color. The opacity and hand of the ink were also considered to ensure the softest print possible without jeopardizing the print or the garment’s longevity.

Throughout the process, we maintained open communication with the client. A sample before production photo was text messaged to the client to ensure the project was progressing as expected. This step was crucial for guaranteeing client satisfaction and ensuring that the final product met their expectations.

In conclusion, this jumbo screen printing project was a testament to our team’s technical prowess and efficiency. Despite the project’s complexity and tight deadline, we were able to deliver high-quality, consistent prints that met the client’s expectations. This project serves as a shining example of what can be achieved with technical expertise, efficient processes, and a commitment to quality in the screen printing industry.

So, next time you’re at the cinema and you see some cool movie merch, remember that jumbo screen printing by Garment Decor!

Contact us!

Garment Decor

Call (855) 942-7636

Email info@garmentdecor.com

Follow Facebook and Instagram