Most Popular

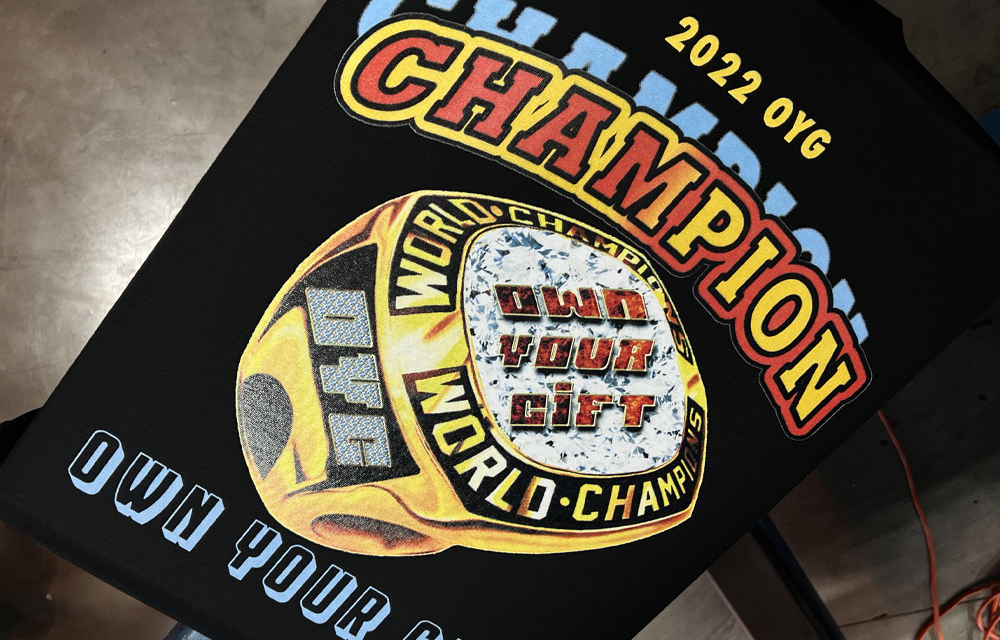

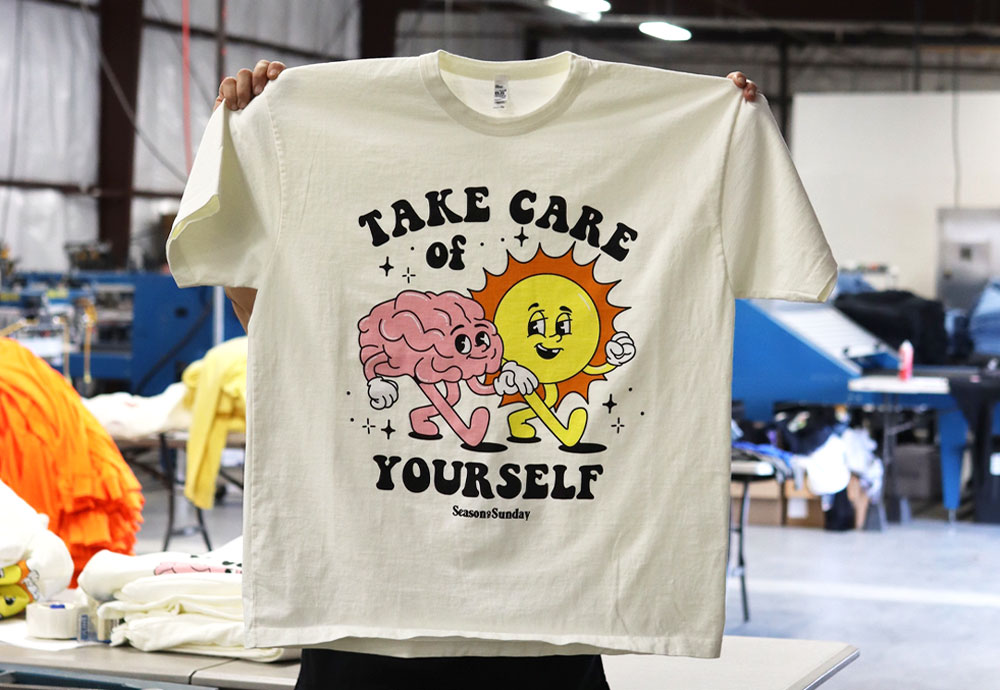

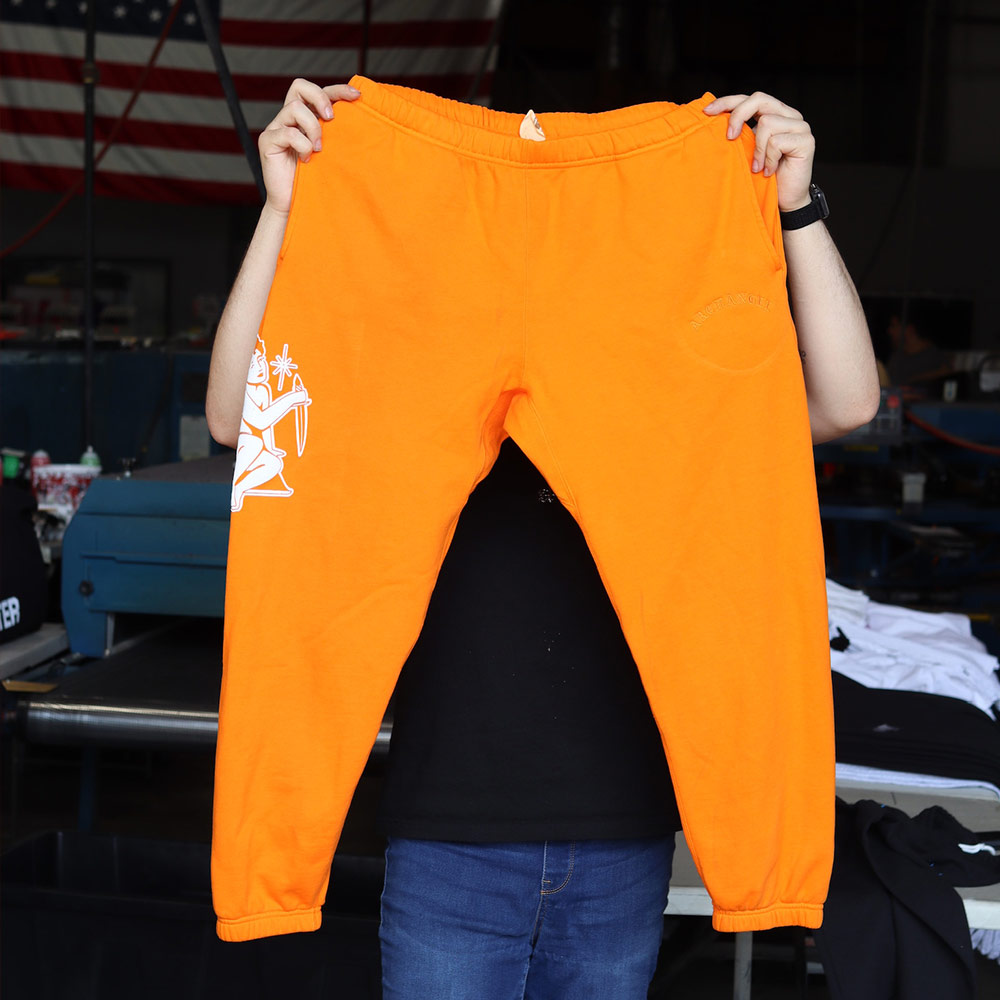

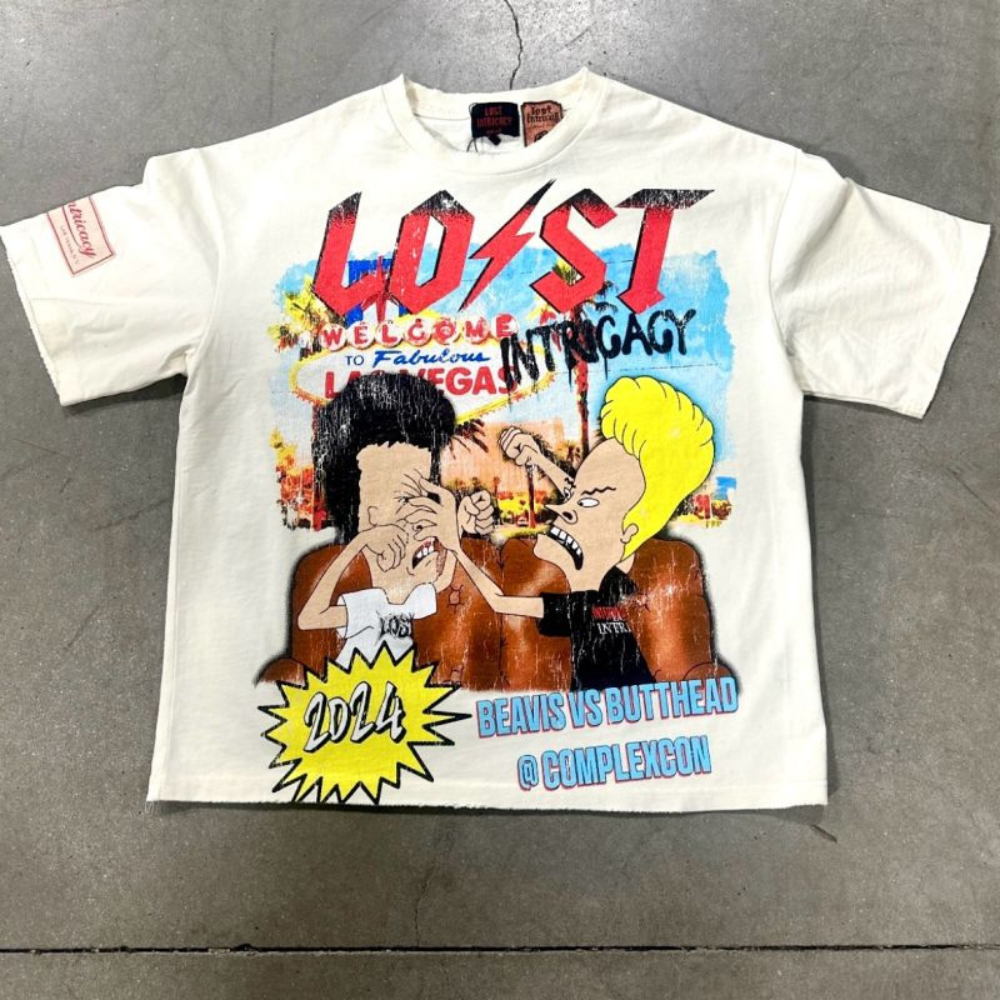

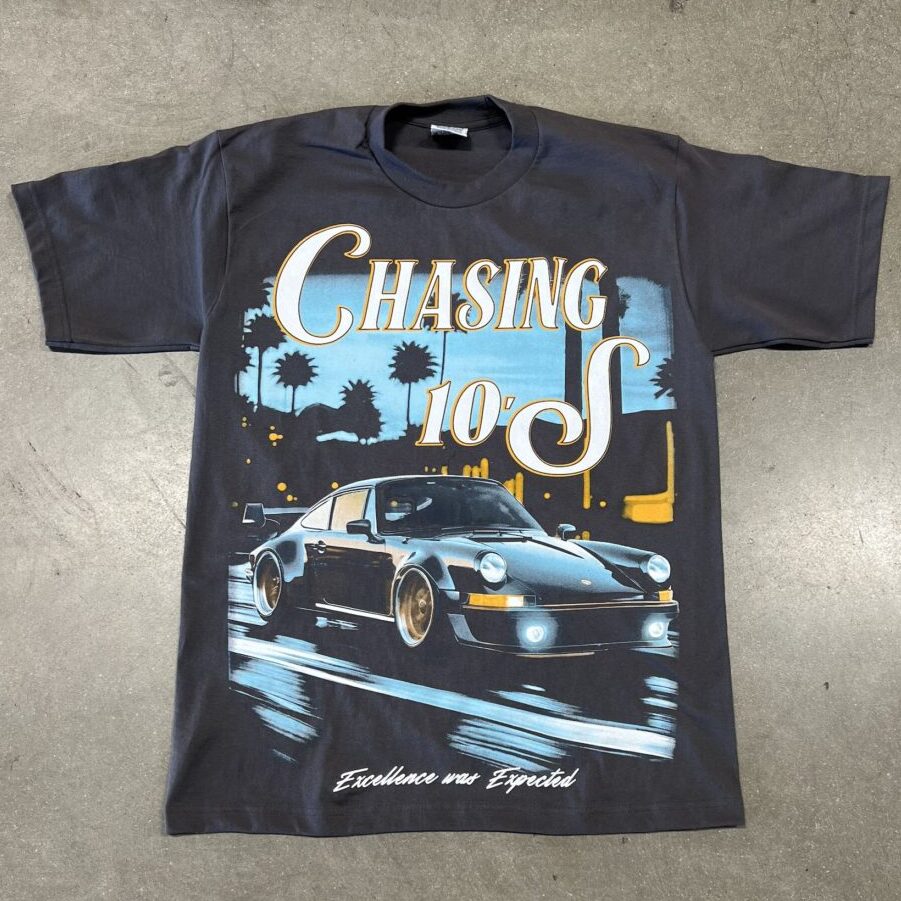

Custom Plastisol Screen printing

Plastisol screen printing is the best choice for creating vibrant colors and detailed designs on everything from t-shirts to tote bags and hoodies. We use premium and opaque (bright) plastisol inks to ensure your artwork is printed professionally. These inks can be printed on a wide range of fabrics including cotton, polyester, blends, spandex, nylon, rayon, & more. We can also custom-mix the plastisol inks to create nearly any custom ink color (Pantone Color). In this page, we'll explain why Garment Decor is the best plastisol ink decorator for clothing brands & businesses in the nation.

- Vibrant, opaque colors

- Custom Pantone matching

- Print on various fabrics

- Add "softee" for a soft touch

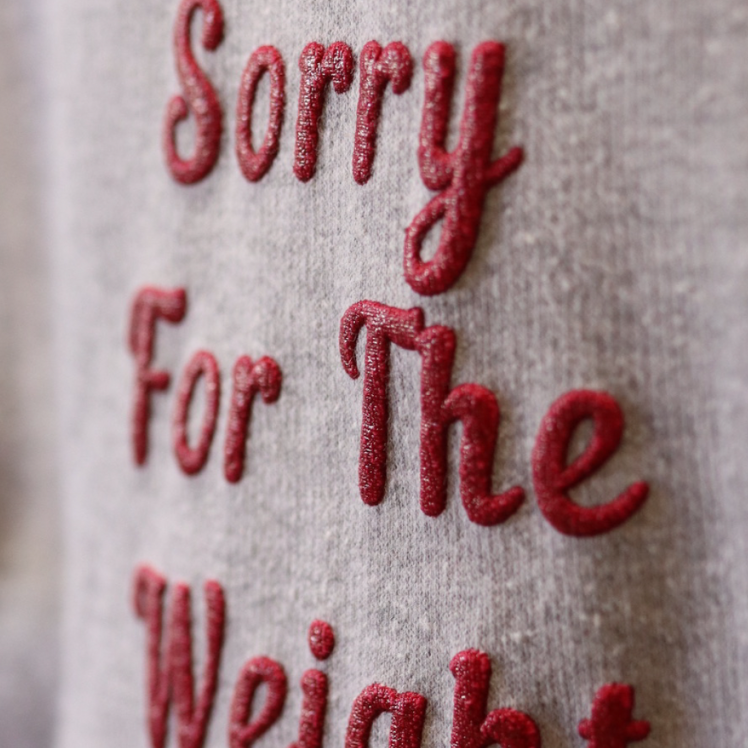

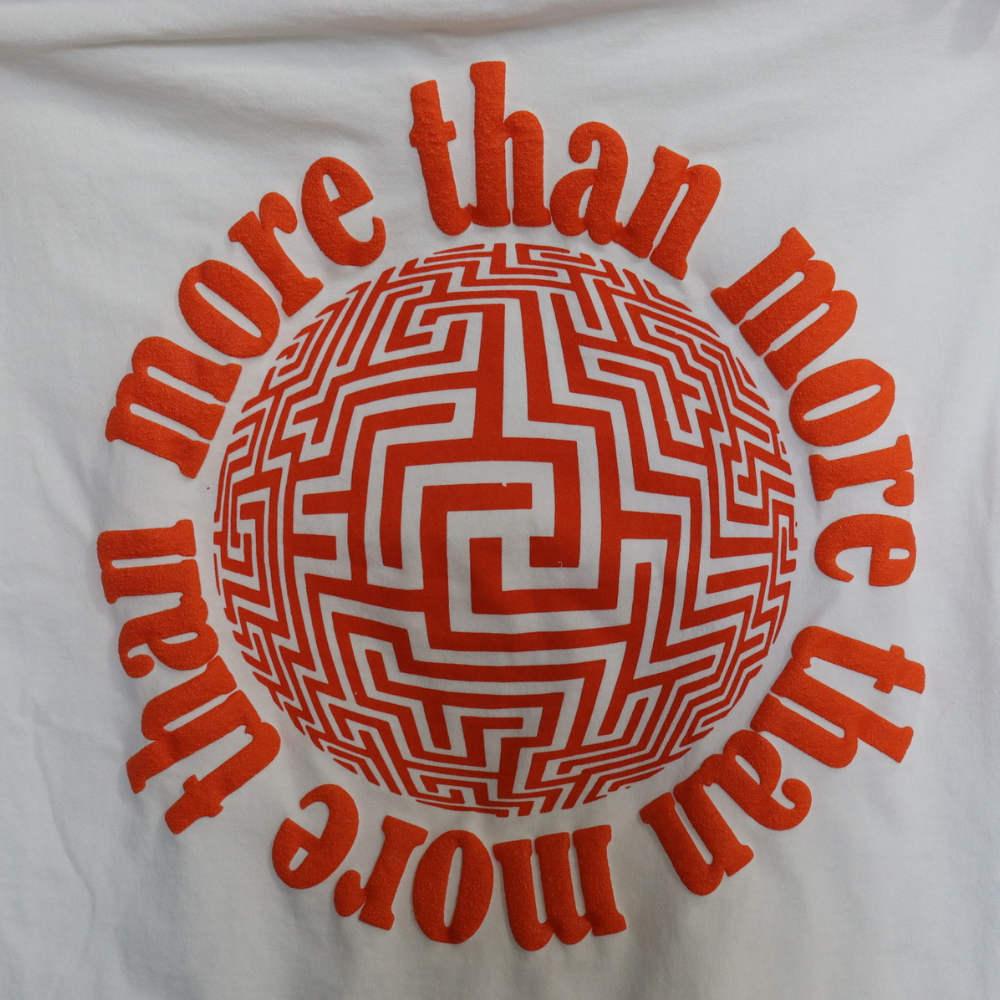

- Upgrade to 3D puff ink

- 24 hour rush service

Creative Plastisol Ink Techniques

Plastisol ink screen printing has been the heart of our screen printing services since 2013. It’s what Garment Decor is known for and has been a core part of our business since the beginning. We love the vibrancy, abilities, and textures of this ink.